6 ways industrial IoT can benefit modern operations

From construction to mining to manufacturing, the Internet of Things offers industries new ways to improve their processes to be safer and more efficient.

Over the last 10 years, data has become an increasingly important to businesses and useful as the technology to collect, store, and analyze it has improved. One of the most prevalent advancements in the industrial world over the last decade has been the introduction of the Internet of Things (IoT), which has become the centerpiece for the fourth industrial revolution, otherwise known as Industry 4.0.

The backbone of industrial IoT (IIoT) is built upon low-powered sensors and internet connected devices, which collect and transmit data to users quickly, informing day-to-day and long-term decisions. By implementing these sensors, industrial leaders can converge internet technology and operational technology, vastly improving productivity.

“Real-time data from sensors and other information sources helps industrial devices and infrastructures in their “decision-making,” in coming up with insights and specific actions,” according to a report from Trends Micro USA. “The data allows industries and enterprises to pick up on errors or inefficiencies in the supply chain, for example, and immediately address them, thus pushing for day-to-day efficiency in operations and finance. Proper integration of the IIoT can also optimize the use of assets, predict points of failure, and even trigger maintenance processes autonomously.”

Industrial IoT covers a wide area of technological advancements in addition to sensors, such as artificial intelligence, machine-to-machine communications, and cloud technology.

Experts agree that as these technologies improve, the demand for IIoT will rise. Forecasts indicate the global IIoT market will reach $751.3 billion by 2023, with the fastest growth in IIoT software. To understand why there are such high expectations for IIoT, let’s take a look at how some of the top industries will benefit.

Industrial IoT offers oil and gas improved regulation and automation

Modern IIoT solutions have made it easier for leaders in the oil and gas industry to monitor their hardware for signs of failure as well as reduce production costs.

Energy is known to be a volatile industrial sector. As market prices for oil and gas fluctuate so frequently, there is pressure on manufacturers to continuously improve collection and refining methods to reduce their costs while maintaining their productivity. Additionally, the collection and refining of oil and gas is a complex process with serious repercussions if there is a failure.

Industry leaders such as Chevron, ExxonMobil, and Shell have all partnered with technology companies to improve their services, from predicting the time for equipment servicing to increasing drilling production.

In fact, according to Naveen Joshi, IoT expert, columnist, and CEO of software company Allerin, there are a number of areas where IoT benefits the oil and gas industry. Here are a few examples:

- Drilling Management: For companies that are drilling offshore or deep underground, it can be difficult to monitor the machinery that, if not handled with precision, can have dire consequences. Using IoT devices, coupled with an IIoT platform, users receive continuous measurements to narrow any margins for error, as well as get alerts ahead of any impending drilling errors.

- Pipeline Monitoring: Pipeline leaks are an important issue in the oil and gas industry, both from a business and humanitarian perspective. Over the past 10 years, pipeline leaks have caused nearly 200 deaths, 900 injuries and $5.75 billion, according to the US Department of Transportation’s Pipeline and Hazardous Materials Safety Administration. By implementing IIoT sensors along pipelines, employees can keep a close watch on potential points of failure to limit physical dangers, and industries can spend fewer resources on continuous human inspections by automating that job instead.

- Increase Long-term Revenue: Oil and gas is extremely competitive, which means companies will need to find areas to cut costs to remain in business. While short-term solutions may help a company stay in the green, they may be detrimental over the long term. By investing in IoT, companies can collect data over the short and long term, using big data analytics to change more big-picture inefficiencies. For example, using IoT sensors, organizations can monitor their levels of inventory in different geographic areas to improve supply chain management. Internet connected sensors can also help identify optimal drilling areas, which for companies such as ExxonMobil, is predicted to increase production by nearly 50,000 barrels-per-day by 2025.

Mining companies use sensors to increase safety and efficiency

Industrial IoT in the mining industry is still in its relative infancy, however industry leaders are already using IIoT to create safer, more effective operational ecosystem.

“IIoT enabled machinery can help optimize material and equipment flow for increased efficiency and yield. Equipment failures can be anticipated and real-time monitoring allows for sophisticated decision making and predictive maintenance strategies,” Mining[Dot]Com reports. “Through IIoT, drilling and blasting can be optimised, leading to improved mine and logistics scheduling.”

Using IIoT companies can monitor efficiencies in all steps of the extraction process, including automated drilling. Mining company Goldcorp is using IIoT to build AI-driven drilling machines that can “detect materials and boundaries and have an automatic guidance system for cutting,” Industry Week reports. Meanwhile, Fortescue Metals Group has outfitted a fleet of trucks with IIoT sensors to tell supervisors when vehicles are not operating at maximum capacity and adjust accordingly, increasing overall revenue.

These sensors can also improve employee safety as well. At Goldcorp, miners have IIoT sensors embedded in their helmets, giving live-updated locations in case of an emergency.

“The increased automation of plant equipment and vehicles enhances safety while reducing costs, removing employees from hazardous situations,” according to Mining[Dot]Com. “Integrating IIoT technology into a complete mine operation can expand ROI by boosting throughput and reducing expenditures.”

Manufacturers experience greater oversight over supply chain

As manufacturers expand their distribution channels to fit a global, digital economy, visibility into supply chain management is crucial to ensure customers receive quality products in a timely manner.

Sensors can also help organize warehouses where products are stored to fit with the demand for the geographical region.

“With the Internet of Things, stocks can be automatically monitored and integrated with customer demands in certain regions; hence, if you are a distributor in a certain region, then you’ll be able to store the optimum number of goods within your warehouse,” Production Engineering Solutions explains.

Through IIoT, employees can also monitor different components of their operations instantaneously, allowing them to keep a keen eye on how their products are moving from start to finish.

“Powered by Low Power Wide Area (LPWA) networks, Bluetooth, GPS, radio frequency identification (RFID), and other technologies, tracking solutions allow manufacturers to visualize exact asset location in real time,” according to IOTTimes. “Smart sensors placed with the products can provide granular data about transportation conditions like temperature, humidity, and light exposure, sending alerts in case of damage or exceeded thresholds.”

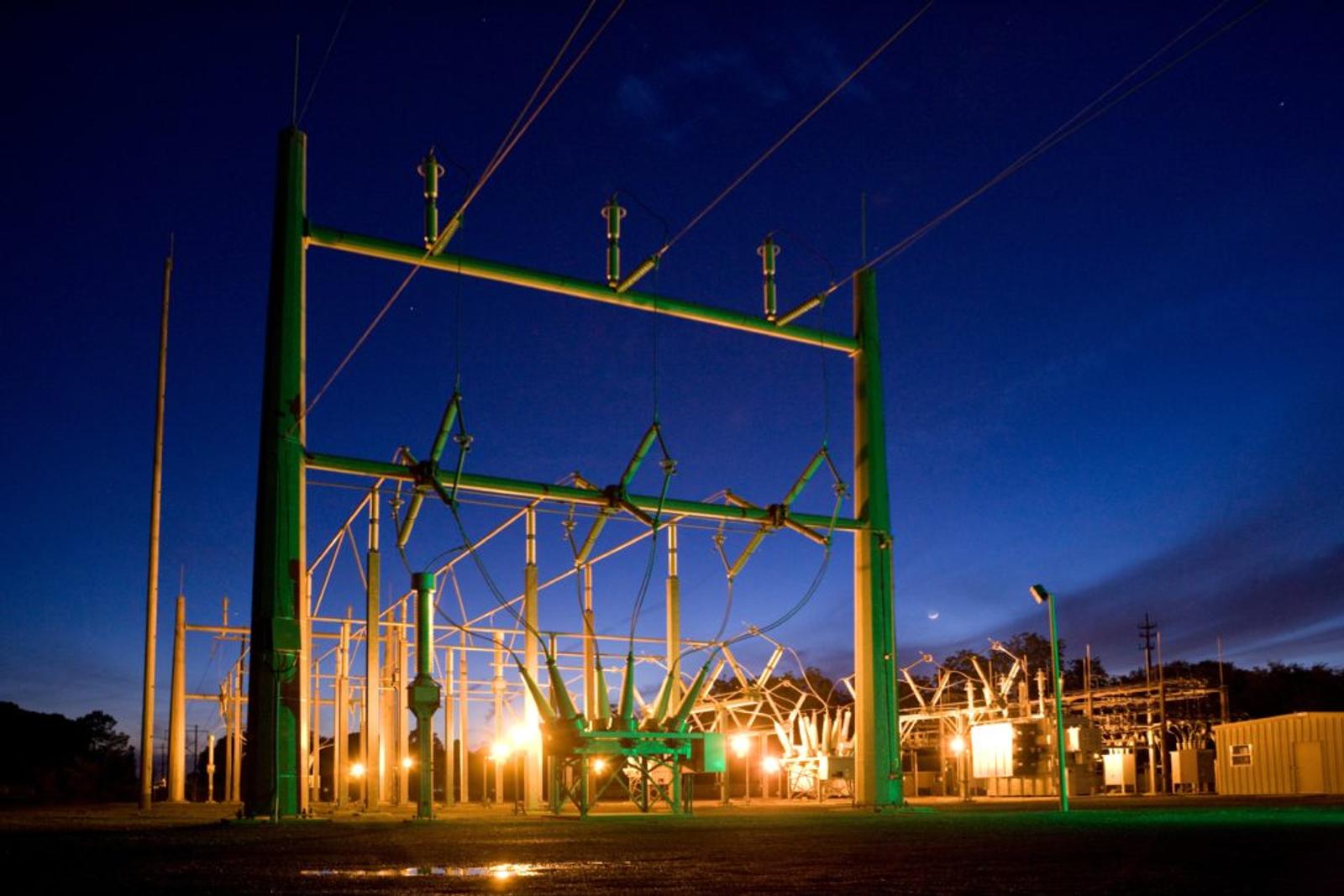

Utilities use IIoT to create energy-efficient smart grids

Utilities companies suffer from a monitoring process that is “rooted in aging technology,” according to John Geiger, Vice President Business Development at software solutions company MACHFU. “This results in an infrastructure that is dominated by legacy and proprietary systems with a historical reluctance to adapt to new, open standards-based paradigms, one that does not facilitate moving to a modern distributed energy resources smart grid.”

The introduction of IIoT for utilities began with Advanced Metering Infrastructure (AMI), a network of complex communications and data collection systems that “allowed for two-way communication of customer, control, and event data,” IOT World Today explains.

The world of IIoT in utilities has since expanded as automation systems have advanced, allowing for greater control of voltage regulation and energy distribution.

Using IIoT, energy companies can restructure their management systems to fit a smart grid worthy of being a part of the 21st-century. Continuous streaming of data from strategically placed sensors can ensure energy nodes are working at optimal capacity and are being replaced when needed. This is especially true for companies working in renewable resources such as wind and solar, where multiple sensors are needed to not only measure the efficiency of each node, but also relevant environmental conditions.

“IIoT for utilities promises empowerment and opportunity enabling utilities to oversee communications that reach across and into the homes and workplaces of their customers,” IOT World Today reports. “With a unified, global solution approach to utility communications, combined with the lessons utilities have already learned about security, privacy and engagement with consumers – utilities should embrace the uncertainty ahead and lead in the IIoT era.”

Railway tracking and maintenance improved by IIoT integration

Trains are the heart of metropolitan areas around the world, in New York City alone, 1.7 billion people rely on the subway system every year. However, many urban, and cross-country railway systems are rife with maintenance issues and a poor level of customer service for riders. However, new forays into IIoT may provide solutions to some of the most prevalent issues for this public transportation service.

Train cars have traditionally been serviced using a reactionary, time-based maintenance schedule. In other words, don’t fix it if it’s not broken. This kind of passive approach to railway operations can lead to train cars going far too long without being properly inspected employees are not considering factors such as use frequency, leading to inefficient travel, unhappy customers, and, in some cases, tragic accidents.

At the Palo Alto Research Center (PARC), researchers are looking into ways to integrate IoT sensors into train cars and stations as part of a new condition-based management (CBM) system make railway operations safer, timely, and efficient.

By introducing IoT sensors into trains that are put into circulation, coupled with an IIoT data dashboard to record and remotely monitor data, railway organizations can predict when a train is likely to need repairs and begin preparing to service those cars.

“Train companies are therefore moving away from TBM to this more predictive paradigm where [operations and management] teams may get a week or even a month’s notice before assets fail, allowing them to prepare schedules and resources to avoid taking a critical train out of service and disrupting the system,” Ajay Raghavan, Strategic execution director at PARC, told Railway Technology. “Providing operators with data on the remaining useful life of an asset one or even six months before it has to be retired enables them to plan ahead for a major capital outlay, for example.”

This solution is not just for maintenance either. The larger the network of interconnected devices, the more seamless a railway system can be. Industrial IoT sensors can be used to measure how trains are moving through the tracks, local environmental conditions, train car geolocation and passenger traffic. Housing all of this information under one management system opens the door for a holistic approach to railway management.

Construction enters the digital age with IIoT

According to this report from the World Economic Forum, the construction industry, despite accounting for 6 percent of the world’s GDP, is lagging behind other industries in adopting technology associated with the fourth industrial wave.

“Most companies in the industry’s many sectors still use primarily manual methods, offer traditional products and services and operate according to established practices and business models,” the report’s authors note. “Productivity has lagged as a result.”

There are many moving parts to a construction site, from heavy machinery to design placement to worker safety, however any useful data within these areas are siloed or not collected at all. Industrial IoT has many safety and productivity implications for construction sites when the IIoT is integrated into these various site components.

“IIoT is digitizing the construction field with numerous sensors that reports all types of data — location, speed, vibration, fuel levels, safety/environmental hazards, raw materials, finished goods, work in process — without traditional manual/paper-based data acquisition,” Jane Ren, CEO of Atomiton, writes for Engineering News Record.

One specific use case for IoT is the ordering of new materials, which can lag due to human error. If materials are not on site in time, it can delay crucial deadlines and be bad news financially for the construction company. With IIoT sensor and AI, ordering new materials can be automated, cutting out the possibility of any late deliveries due to employee oversight.

Overall, the inclusion of IIoT sensors unifies a plethora of moving parts in a construction site by aggregating data across many, otherwise separated, pieces. By doing so, site managers can monitor the entire project easily and ensure projects remain on schedule.

“Digital construction can reduce project disruptions by increasing equipment uptime, quickly locating movable equipment, reducing idle time and decreasing unplanned downtime through predictive maintenance,” Ren writes.

The use of IIoT is still early, with some industries further along than others. However, the fourth industrial revolution is approaching fast, and IIoT will only have a larger role to play, which means now is the time to invest.