Digitize to meet the demands of Industry 4.0

The manufacturing industry is at an inflection point with the acceleration of automation and the power of AI. Harnessing these innovations is key to global competitiveness. Cellular IoT plays an important role.

Transform your manufacturing with Cellular IoT

Streamline operations to maximize uptime and improve yield

Plan maintenance in advance to avoid unplanned downtime

Collect data from connected sensors to power analytics and AI for Industry 4.0

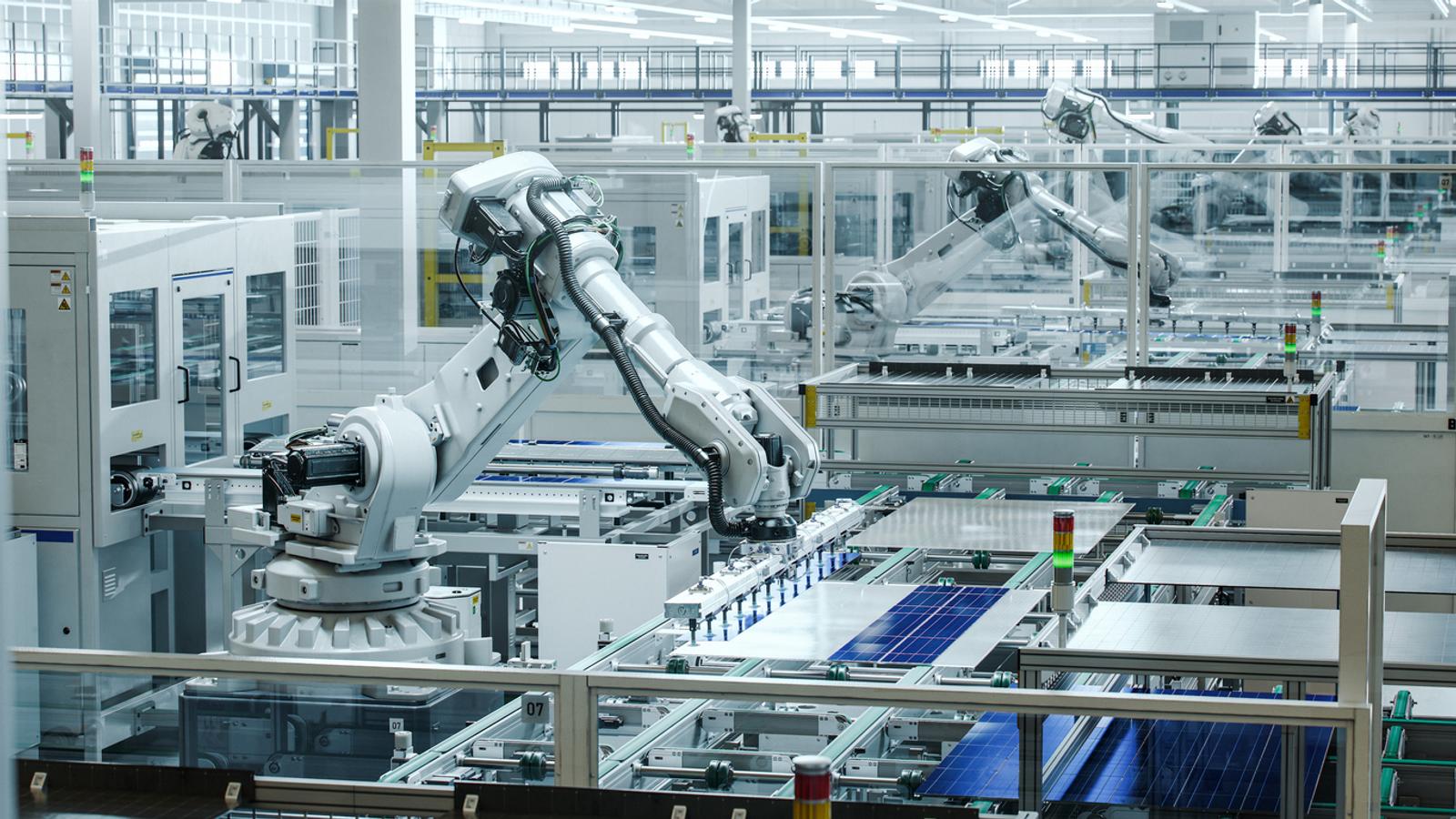

Robots and automation

In 2024, there were more than 3.9 million operational robots around the globe. Usage of collaborative robots (cobots) that work alongside human workers is increasing with advances in sensors and vision technologies. Mobile manipulators (MoMas) – a cobot arm with an autonomous mobile robot – likewise uses sensors and cameras to perform inspections and maintenance tasks. Fast, reliable connectivity is critical.

AGVs

Automated Guided Vehicles (AGVs) increasingly play an important role in the automation of manufacturing and warehouses, growing at a 9% CAGR through 2030. Workers can focus on more critical tasks while AGVs move materials, load goods at docks, and more. These on-the-move vehicles need the non-stop connectivity provided by Cellular IoT.

Augmented Reality (AR)

To help lines run more efficiently and improve worker safety, manufacturers are incorporating digital technology like augmented reality. AR enables workers to interact with digital objects and data as if they were real. This technology is also very valuable for training. With many AR activities taking place on the move, Cellular IoT is perfect.

Artificial Intelligence (AI)

IoT sensors and devices feed AI terabytes of data to orchestrate the automation anticipated by Industry 4.0, helping manufacturers optimize operations, maximize production, and improve safety for workers. Given those significant benefits, it’s no surprise that the global AI in manufacturing market is estimated to grow from $3.2B in 2024 to $20.8B by 2028.

Predictive maintenance

Cellular IoT sensors provide critical information like machine flow, temperature, and visuals. This enables manufacturers to predict when maintenance will be needed and also to identify unusual patterns that might indicate equipment malfunctions. With Cellular IoT, no connectivity to overburdened Wi-Fi networks is needed.

Water and wastewater treatment

IoT sensors and video collect real-time data on water flow, quality, and chemical levels to help operators adjust flow and adjust treatment processes to ensure optimal performance. Cellular IoT enables the monitoring to take place in any setting.

FAQs

Do I need Wi-Fi connectivity to activate my IoT devices? I don’t have reliable Wi-Fi in my facility.

One of the most powerful features of Cellular IoT is the ability to provision and manage via cellular networks. That means you do not need to connect the device to Wi-Fi to activate or manage it. This eliminates both the Wi-Fi reliability issue and the complexity of password management.

What is the value of having both wired and wireless connectivity?

Wi-Fi plus Cellular IoT powered with 5G as the back-up ensures the outage-free connectivity needed to deliver on the promise of smart manufacturing. A recent study revealed that 45% of surveyed manufacturers expect that 5G specifically will have the largest impact on manufacturing connectivity in the next three to five years, outpacing all other wireless technologies. Read more about combining Wi-Fi plus cellular.

I’m worried about managing my IoT devices as we ramp up our digitization process.

It can become a challenge to manage a fleet of IoT devices. With the Hologram Dashboard, we’ve enabled machine monitoring at scale. With a shared pane of glass, your team can automate your SIM lifecycle and get detailed analytics across your entire fleet. Intelligent alerting tools allow you to spend less time manually managing your IoT devices. We also provide all of the same data via our API.

Elevate your connectivity with Cellular IoT

Our robust coverage ensures your device will work right out of the box with zero end-user setup or configuration.

Our Outage Protection SIMs automatically fallback to a 2nd mobile core for guaranteed availability.

A single source of truth for your operations – any size fleet, anywhere in the world, anytime.